To choose solar street lights, it is essential to understand several key concepts. The first is lumens and watts, the second is lux, the third is color temperature. Lumens represent the output brightness. Lux signifies the actual brightness of illumination. Color temperature refers to the color of light emitted by a light source.

Lumen Requirements for Outdoor Street Lights

The lumen output needed for outdoor street lights varies based on factors such as pole height, road width, and ambient light conditions. It’s essential to consider recommended illumination levels for different road types:

Lumen Output by Pole Height:

Selecting the appropriate lumens and watts can significantly enhance both lighting quality and energy efficiency. For detailed guidance and examples, please refer to the link: Lumens vs watts: lumens to watts conversion chart

Lux signifies the actual brightness of illumination, measuring light flux per unit area, and is commonly used to assess lighting effectiveness and suitability.

Highways:

Values apply to asphalt; concrete requirements can be reduced by up to 30%.

Urban Roads:

Rural Roads:

For more details, please refer to the link: [What is Lux in Lighting? Solar Street Lighting Lux Level standard]

Choosing the right color temperature for solar street lights is crucial for achieving the desired ambiance and visibility. Color temperature is measured in Kelvin (K) and affects how light appears; warmer temperatures (below 3000K) emit a yellowish light, creating a cozy atmosphere, while cooler temperatures (above 5000K) produce a bluish-white light that enhances visibility and safety.

When selecting the color temperature for solar street lights, the following standards are worth considering:

Road lighting color temperature suggestions:

Highway lighting: not more than 5000K, usually choose low and medium color temperature, but in some projects can be used 5700K or higher.

Airport road lighting: no more than 4000K, glare control lens should be added.

Residential road lighting: Low to medium color temperature is recommended, usually kept below 4000K.

Rain and fog road lighting: it is recommended to use low color temperature lamps, the recommended range is 2700K-3500K.

Road lighting in commercial areas: High color rendering index (CRI), low to medium color temperature light sources are recommended.

Parking lot lighting: 5700K-6500K color temperature is recommended.

Garden and industrial lighting: Warm color temperature 2700K-3000K is recommended to create a warm and relaxing atmosphere.

For more details, please refer to the link: [Choosing the Right Color Temperature for Your Solar Street Light Project]

After understanding the basic parameters of solar street lights, we can determine the appropriate height and spacing to determine the required quantity according to the project application scenario and the required standards of the project, and then choose the appropriate brightness of solar street lights, pole height, battery type, etc.

Installation Distance Guidelines for Street Lights

Road Width: 3-4m; Pole Height: 3-4m

Distance Between Poles: 10m

Road Width: 5-7m; Pole Height: 5-7m

Distance Between Poles: 10-25m

Road Width: 8-12m; Pole Height: 8-12m

Distance Between Poles: 30-40m

Main Traffic Arteries (20m wide); Pole Height: 12-14m

Distance Between Poles: At least 40m

For further details, please refer to the link: [Solar Street Light Height and Distance Spacing Calculation]

Lithium iron phosphate battery (LiFePO4): Despite the higher price, it provides higher energy density, longer service life (usually up to 8-10 years) and better stability, suitable for solar street lights.

NiMH battery (NiMH): environmental protection is better, but more maintenance, suitable for high energy consumption equipment, not suitable for low power recycling of solar lamps.

Nickel-cadmium batteries (NiCd): Despite their low price, they are not recommended for solar street lights because of the “memory effect” and toxicity problems.

Lead-acid batteries: although low cost and stable voltage, but large volume, short service life, frequent maintenance.

Gel cells: A modified version of lead-acid batteries that performs better but may be more expensive and suitable for extreme climatic conditions.

For further reading, please refer to the link: [Solar Street Lights Battery Comprehensive guide]

Material Requirements:

Wall Thickness Requirements:

Considering these details, users can select solar light poles with suitable materials and wall thickness to ensure longevity and reliability based on their budget and installation requirements.

For further reading, please refer to the link: [Guide to Selecting Solar Street Light Poles]

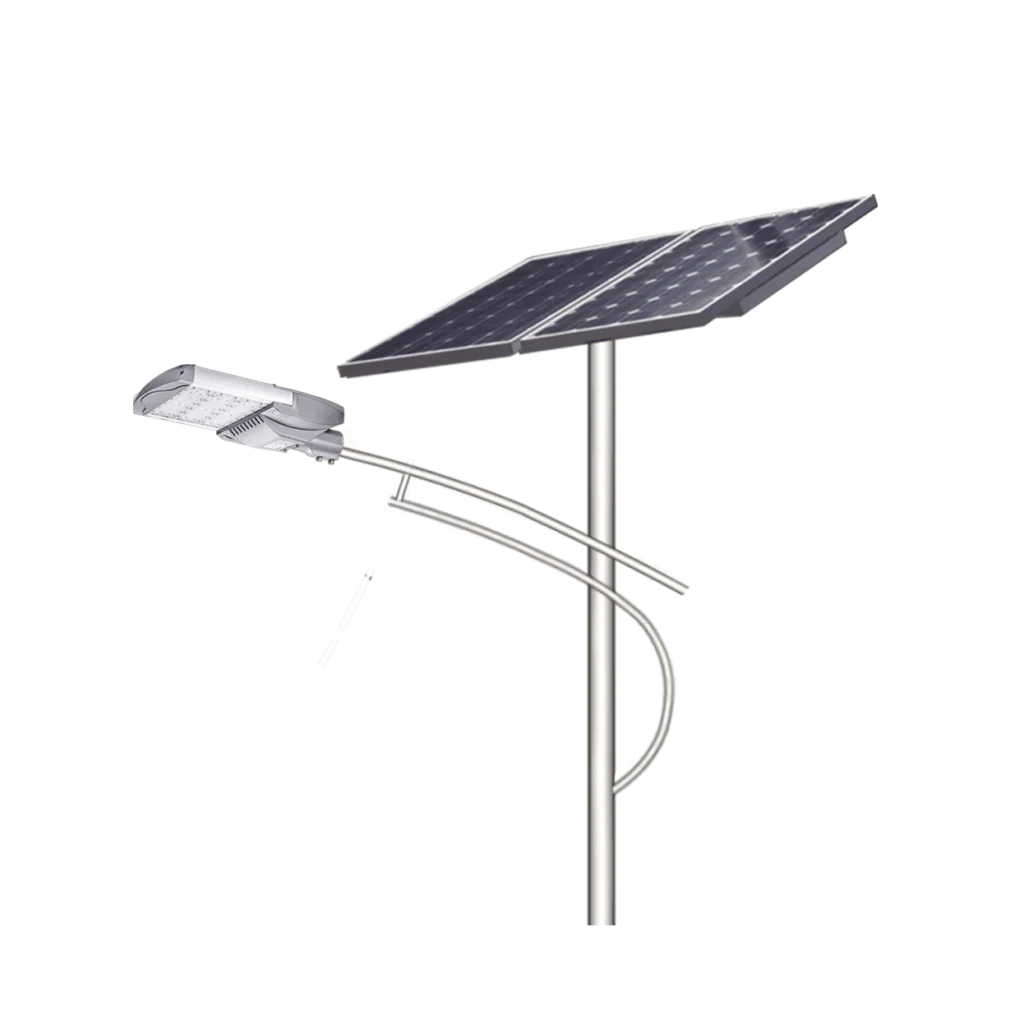

Optimal Angle and Orientation: Solar panels can be installed at the best angle and direction to maximize sunlight absorption and enhance photoelectric conversion efficiency. For instance, in regions like Jiangxi classified as type 4, the total annual solar radiation is between 4200 to 5000 MJ/m². By properly setting the tilt and azimuth angles, the illumination efficiency of the panels can be significantly increased.

Reducing Shadow Impact: Modular design can avoid issues where light poles or other objects block solar panels and affect illumination efficiency. This is particularly important in urban areas with a high density of buildings and trees; a modular design can better avoid these obstructions.

Minimizing Material Waste: Modular design allows more precise selection of installation locations for each component, thereby reducing unnecessary material waste. For example, solar panels can be installed in areas with the best light conditions without sacrificing efficiency due to height restrictions of light poles.

Lowering Installation Difficulty: Modular design simplifies the installation process, reducing risks and costs associated with high-altitude work. For instance, batteries and controllers can be installed on the ground, lowering construction difficulties and costs.

Protecting Components: Modular design better protects individual components, especially the batteries. Installing batteries on the ground or inside an underground control box helps avoid the adverse effects of high temperatures and humidity, prolonging their lifespan. For example, in the solar streetlight systems in the cold regions of Qinghai, gel acid batteries are widely used for their cold resistance and long lifespan.

Reducing Damage Risk: Since each component is installed separately, even if one component fails, it does not affect the operation of the entire system. For example, if a solar panel is damaged, it can be replaced individually without needing to dismantle the entire light pole.

Lightning Grounding: Modular design can better facilitate lightning grounding. For example, a metal lamp post can also serve as a lightning rod and down conductor, ensuring that the ground resistance does not exceed 10Ω, thereby increasing system safety.

Low Voltage Operation: The operating voltage of modular solar streetlights is generally 12V or 24V, classified as a safe voltage that does not pose electrocution risks. For example, the solar streetlight system in the Yunxi community in Tong’an, Xiamen, received positive feedback from clients and owners after implementation, achieving good social benefits.

Intelligent Control: The controllers of modular solar streetlights can use microcontrollers as core processing chips, featuring all-around, fully automatic, multifunctional, and high-efficiency capabilities. For instance, MPPT technology (Maximum Power Point Tracking) can ensure that even on rainy days or deep discharges of batteries, the system can still obtain maximum current, thereby enhancing system reliability.

Automatic Adjustment: The controller can automatically adjust the lighting duration of the fixtures based on the remaining capacity of the battery, ensuring the system operates at the minimal workload, which extends the battery’s lifespan. For example, the solar controller adjusts its operating mode according to the SOC (State of Charge) value, enabling the battery to quickly return to the float charging state, effectively protecting it.

Building D, Huashengtai Technology, Baoan District, Shenzhen, China

© 2026 All Rights Reserved.