Effective Solutions to EVA Glue Shortage and Photovoltaic Ribbon Offset

Addressing EVA glue shortages, preventing photovoltaic ribbon offset (especially the exposure of white due to deviation), and solving EVA leakage or insolubility issues require a multifaceted approach involving supply chain management, material substitution, process optimization, and quality control. Here are the specific strategies and measures:

Addressing EVA Glue Shortage

Optimize Supply Chain Management

- Establish a comprehensive inventory management system to monitor EVA glue stocks in real-time and ensure timely replenishment.

- Collaborate with multiple suppliers to avoid supply interruptions due to issues with a single supplier.

- Forecast future EVA glue demand through data analysis and plan purchases in advance to ensure stable supply.

Seek Alternative Materials

- Research and test other polymers, such as POE (polyolefin elastomer) or PVB (polyvinyl butyral), that may outperform EVA glue in certain properties.

- Partner with material suppliers and R&D institutions to develop new materials suitable for photovoltaic module encapsulation that meet requirements in transparency, adhesion, and aging resistance.

Increase Utilization of Existing Materials

- Optimize the use of EVA glue to reduce waste and increase material efficiency.

- Use precise coating and spraying equipment to ensure uniform distribution of EVA glue and prevent excessive use.

- Regularly inspect and maintain production equipment to ensure efficient operation and reduce material loss.

Preventing Photovoltaic Ribbon Offset (Exposure of White)

Improve Welding Process

- Use high-quality EVA glue and adjust its formulation to include additives such as Cyasorb UV 531, Tinuvin 770, and Naugard P to enhance adhesion and durability.

- Optimize welding parameters such as temperature, time, and pressure to ensure firm adhesion between the ribbon and cells.

- Adopt advanced welding equipment, such as automatic welding machines, to increase welding precision and consistency.

Control Environmental Conditions

- Maintain stable temperature and humidity during production to avoid adverse effects on EVA glue performance due to environmental changes.

- Utilize a closed production environment to minimize interference from external pollutants and ensure optimal curing conditions for EVA glue.

Enhance Mechanical Support

- Use fixtures or other mechanical devices during welding to secure the ribbons and prevent shifts during lamination.

- Design a rational module structure to ensure uniform stress distribution across the ribbon, reducing shift caused by uneven stress.

Regular Equipment Maintenance and Calibration

- Regularly check and maintain welding equipment to ensure proper operation and prevent ribbon offset due to equipment failure.

- Calibrate equipment periodically to maintain precision and stability during production.

Implement Rigorous Quality Control

- Set multiple quality inspection points in the production process to quickly identify and correct ribbon offset and other issues.

- Use automated inspection equipment, such as vision inspection systems, to enhance detection efficiency and accuracy.

- Train production staff to improve their operational skills and quality awareness, ensuring every step follows standards precisely.

Prevent Ribbon Deviation (Exposure of White)

Adjust Rollers and Drums

- Ensure all rollers and drums are installed perpendicular to the longitudinal centerline of the tape machine to prevent ribbon offset.

- Install cleaners on the rollers to promptly remove adhering materials and reduce uneven tape stress.

Optimize Dropping Points

- Adjust the drop hopper position to center materials on the tape, preventing offset due to material eccentric accumulation.

- Install deflectors or modify the drop cylinder section shape for more concentrated material drops.

Use Self-aligning Rollers

- Install self-aligning roller groups to generate lateral additional force and reposition the ribbon correctly by rotating the stand around the axis.

- Ensure the mounting position of self-aligning rollers is correct to fulfill offset correction functions.

Enhance Personnel Training

- Improve operators’ technical level to ensure the correct installation and use of tape machines, avoiding ribbon offset due to incorrect operation.

- Establish a strict reward and punishment system to penalize incorrect operations and reward exemplary performance, motivating attention to work quality.

Addressing EVA Leakage or Insolubility Problems

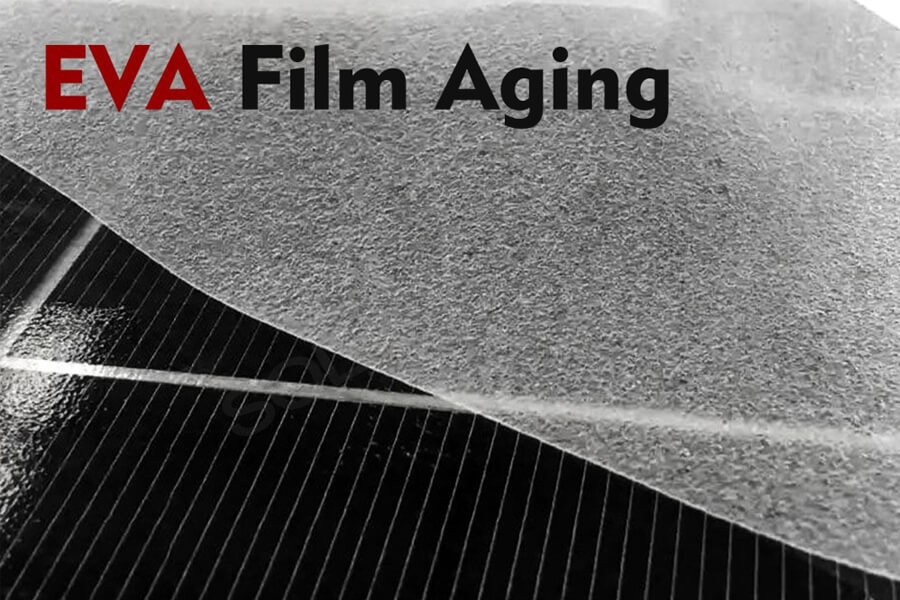

Optimize EVA Film Formulation

- Choose appropriate EVA resins to ensure good flow and cross-linking properties, such as selecting resins with more short branches, small crystalline points, similar molecular weight distribution, and lower melting and crystallization points.

- Add suitable cross-linking agents and co-crosslinking agents like peroxides and silane coupling agents to enhance EVA film cross-linking and stability.

Improve Production Processes

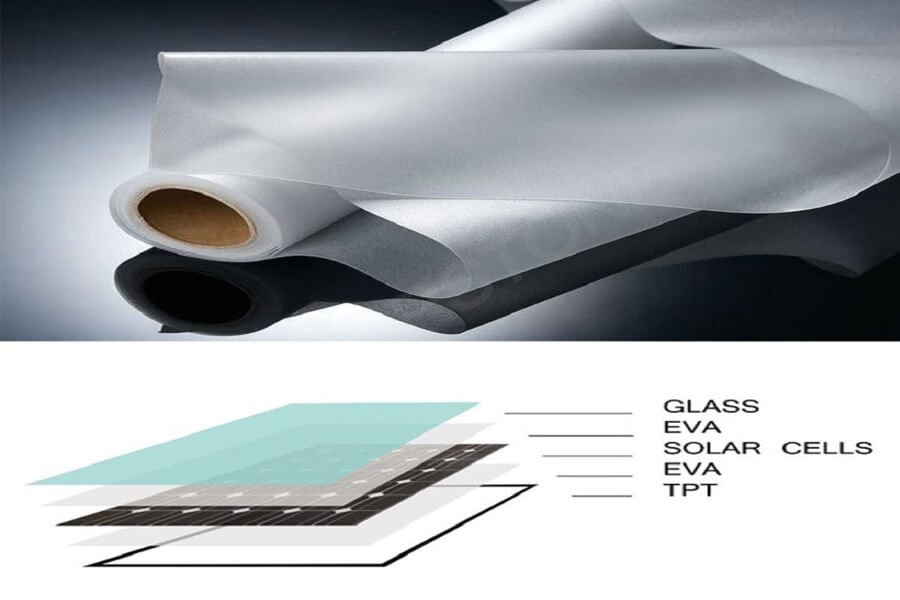

- Optimize the lamination process to ensure the EVA film fully fills between glass layers and backplane, avoiding bubbles and voids.

- Control lamination temperature and time to ensure EVA film cross-links adequately within the optimal temperature window, enhancing its rigidity and toughness.

- Evaluate the EVA film’s cross-linking process and final gel content using differential scanning calorimetry (DSC) and toluene solvent extraction methods.

Equipment Maintenance and Adjustment

- Periodically inspect and maintain lamination equipment to ensure proper operation, avoiding leakage or insolubility due to equipment malfunctions.

- Adjust the pressure and speed of the laminator to ensure even force distribution on the EVA film, preventing excessive local pressure leading to leakage.

Enhance Quality Control

- Establish multiple quality inspection points to quickly identify and correct EVA film leakage or insolubility.

- Utilize automated inspection equipment such as electronic tensile testing machines and rotational rheometers to assess the mechanical and rheological properties of EVA films and ensure compliance with quality standards.

- Train production staff to enhance their operational skills and quality consciousness, ensuring every step is executed according to standards.

By implementing these measures, photovoltaic plants can effectively navigate EVA glue shortages, prevent photovoltaic ribbon offset and white exposure, and resolve EVA leakage or insolubility issues, thus ensuring the high quality and reliability of photovoltaic components, improving overall power generation efficiency, and extending system lifespan.